The Real Dirt on Harvest – Part Two

The Cellar

It’s your friendly Melville investigators here ready to continue our exposé of the ‘real dirt’ about harvest. It’s another early morning and we’re gearing up to meet the cellar crew and check out what’s happening with them. Last week we drove out to the vineyard and survived an overnight pick (we’ve got pictures and dirty boots to prove it!) Today, we’ll get down to the nitty-gritty of what happens after the fruit is delivered…

The mission possible: Wake up early and get to the winery before the sun comes up… to meet our cellar crew, who arrive on-site at a lazy 4 am. It’s pitch dark this early, but the stars are out over the Sta. Rita Hills and it feels magically lit as we make our way down the Poplar-lined driveway (yeah, the headlights help too,) and slowly roll into a parking spot at the winery. Brr… the air is cold here in late October—but we’ve got our jackets and our phones (for pictures!) and we’re ready to see what this harvest fuss is all about…

Walking by the front vineyard, we can hear the sound of activity behind the building … some beeping… is it a truck? Some voices… who’s all here? And some music… could it be reggae? No Jerry? Let’s find out.

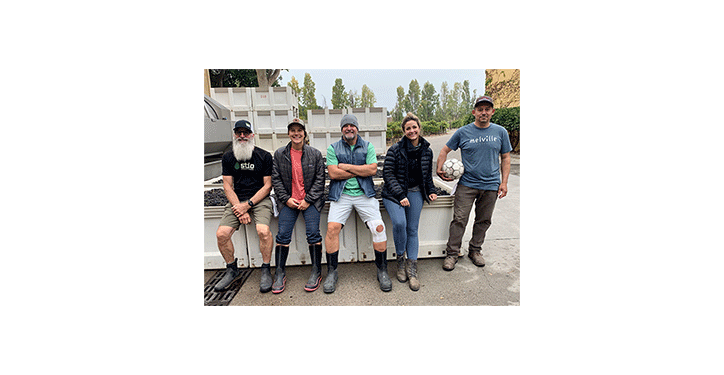

First things first… who is this so-called cellar crew? You might have seen some of their friendly faces around if you’ve been fortunate to pay us a visit—there’s Chad, Brittney, Lee, and Chepe. They’re the “core four” day in and day out, occasionally helped by an intern or special guest. (Um… we really don’t know if you qualify to be one of those, but we can put you on the waiting list for next year.)

Their first task, some would say the most important of the day, is—COFFEE! If you’ve ever been on an airplane, you know to put your oxygen mask on first, then tend to your baby. Same here. Nothing would get done fast enough if this team didn’t have the appropriate provisions… pre-programmed to start at 3:45 am, a pot of don’t panic, it’s organic coffee (from local company Green Star) is brewed and ready first thing.

Meeting together as a team, they fuel up and prepare themselves for the long day of receiving the fruit and guiding it through their little ole’ journey into wine. Coffee is so key during harvest time that the beans are bought in 5-pound bags. This wound-up crew is pinning on it and ready to work straight away… having tasted the results of prior harvests, there are no complaints here. Can we bum a cup though?

Before we go further, we’d like to address something crucial to our winemaking philosophy. You might have heard us say things like “when the fruit is harvested, the wine is practically made.” What does this mean, you ask? If you look to the west side of the building and see stacks of fruit-filled bins—you can smell the ripe, freshly-picked fruit, but yes we know, it doesn’t look ready to drink.

Here it is in a nutshell… our emphasis on wine-growing (nurturing the land, the vines, and the fruit through our organic and sustainable farming methods, along with Mother Nature) means that once the fruit is picked, we consider the wine to be practically made… okay, okay, Brittney might say there’s still a lot of work to do, but really our mission at this point is to gently provide the optimal environment for the fruit to express their innate, yet gently guided, characteristics into the delectable wines we will enjoy in the future.

Translation… the fruit is picked and delivered to the winery—there’s lots of cellar work to do, but it’s work that isn’t doing too much work, but it still makes great wine from the previous work of the farmers and Mother Nature working all year long, and the vines that worked so hard to grow… got it? Work on that – quiz on Tuesday.

Getting back on track, once the coffee has been properly consumed, the team heads out to the crushpad to set up. When the fruit arrives from the vineyard, it’s weighed and “staged”—bins are put in order for gentle processing, the plan is discussed and the equipment is cleaned and ready to go… who’s got dibs on the forklift? Before they start processing, however, they mosey (just kidding they bolt for this) into the barn for a morning workout. Time for… the punch-down party!

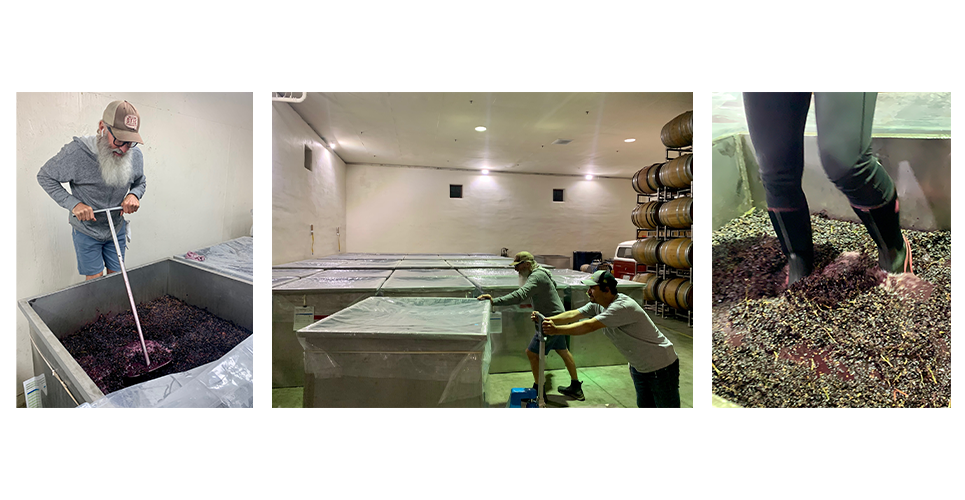

Imagine the “Rocky” theme playing as the team heads into the barn to begin one of the most strenuous activities in the cellar… the punch-down by hand. This starts in the cold room, where fermenters (1.5-ton stainless steel bins) filled with fruit from the previous day are “cold-soaking.” Hand punching down these fermenters is no easy stomp in the park… it takes three strong people about 2 hours to do the first round. (Have you seen the guns on Chepe?)

Why are they doing this? While the fruit is in a fermenter, the solids rise to the surface. When they punch-down with a hand tool (or foot-stomp if there are whole clusters) they’re breaking up the solid matter and submerging it back into the liquid. The more it’s broken up, the more the flavors, color, and tannins will be extracted—that’s what they want, and that’s what we want. It’s an activity that happens 2 times per day, every day, for weeks and weeks… until the fruit is ready to be pressed. Many wineries use a machine “pump-over” to try to do the same process… but the punch-down by hand gives us our best result, and although it’s arduous and time-consuming… it’s incredibly worth it.

After the first set of punch-downs, the crew is ready for a well-deserved break. What comes next? Crushpad soccer! Sports during a break? Who are these beasts? Okay, it’s pretty cool watching them kick the ball around on the crushpad, as the sun rises over the mountains to the east… you feel like the only people up and this place is all yours. Soccer time is bonding time—they’re moving and laughing, having a moment of fun. Everyone’s got their unique “moves” too (or so they think). Chepe’s is called “the olé.”

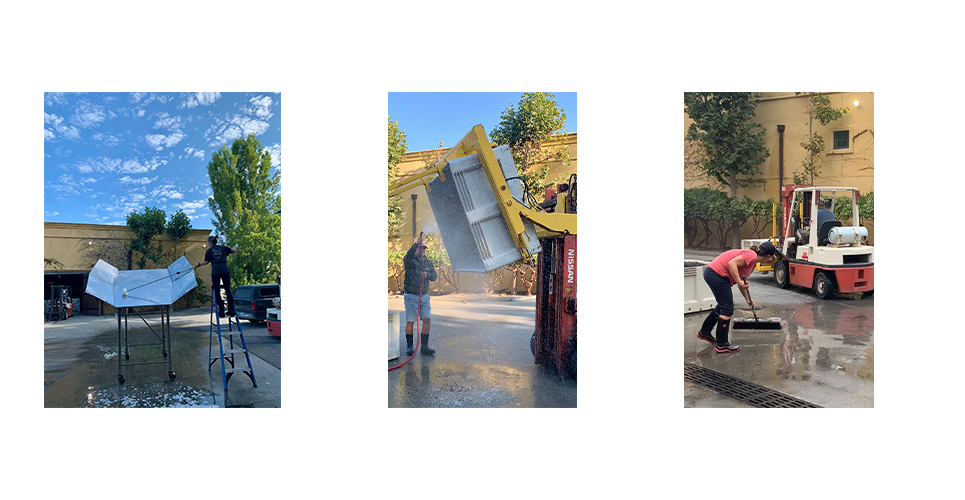

After the crew has complemented each other enough on this highly-skilled footwork—it’s off to processing they go, hi-ho. But wait, there’s more! Before they can actually “process” the fruit, they have to… CLEAN. “We do a lot more cleaning than winemaking around here,” says Chad. Who are we to disagree? His name is on the bottle. Before they pretty much do anything, they clean. After everything, they clean. Someone’s always got a hose in hand.

“Think about if you’re having a dinner party… and you have to clean all your pots and pans, and place settings before the party… then you use them at the party, then clean them all over again afterward. It’s like that with processing (and pretty much everything in the cellar) cleaning all day, every day… and we take pride in it.” That is Chad talking Melville. Again, we’ve tasted the end product, so it works for us and we’re grateful things are so well-tended to. Clean away, Mr. Clean and friends.

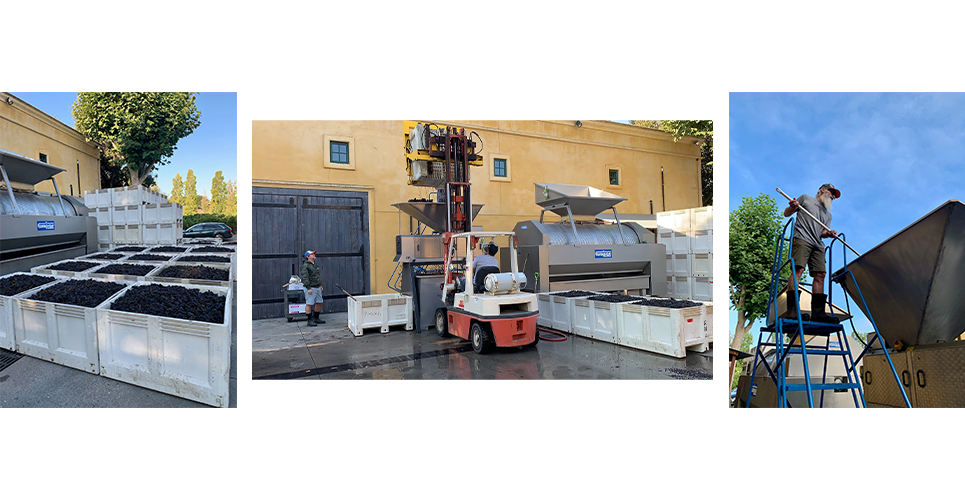

Now let’s get to the nitty-gritty. “Processing” the fruit means gently guiding and providing the natural environment for the grapes to continue their wine evolution. The crew uses a forklift to lift the picking bins and drop the fruit into a machine called “the hopper” which utilizes gravity to destem the fruit. The fruit selected to remain as “whole cluster” slides down the sorting table, which is called “La Mesa,” (how very original) straight into a fermenter. Lee has named the forklift “La Cucaracha” for some reason, and now we’ve got that song stuck in our head. We have to admit—it does look kinda buggy.

Whoever’s got dibs on the other no-name forklift moves the fermenters into the barn. They’re then moved by pallet-jack (that’s a tool, not a person) into the 40-degree cold room where the fruit is “cold-soaked” for a week for a pre-fermentation maceration–basically extracting the flavor, tannins, and color before the alcohol kicks in… kind of like a marinade. So relatable—we too recommend a good marinade before alcohol kicks in.

The fermenter is tarped, and gassed with CO2- what? Why? Because CO2 is heavier than oxygen, and it fills the space between the fruit and the tarp, pushing out any oxygen, keeping an anaerobic environment. Got it–no aerobics allowed here unless you’re the one foot-stomping.

So the fruit’s in the barn now, but what happened to those poor little stems that didn’t make the cut for “whole cluster,” you ask? They’re collected and then either added to our compost or shared with the goats at nearby Motley Crew Ranch… and we sure Dr. Feelgood* about that! (*Motley Crue is an ‘80s metal band and this was one of their songs–saved you from Google).

Back in the cold room – the fermenters get either a foot stomp or a hand punch-down once a day, then after a week they come out and settle into the barn… where foot stomps and punch-downs continue twice a day. All in all, our Pinot Noir goes through this process and total skin contact for 28-35 days… to put it in perspective, most wineries allow skin contact for 10-14 days. Our long skin contact is designed to extract the colors, tannins, and flavors that turn the fruit into our beloved Melville wines.

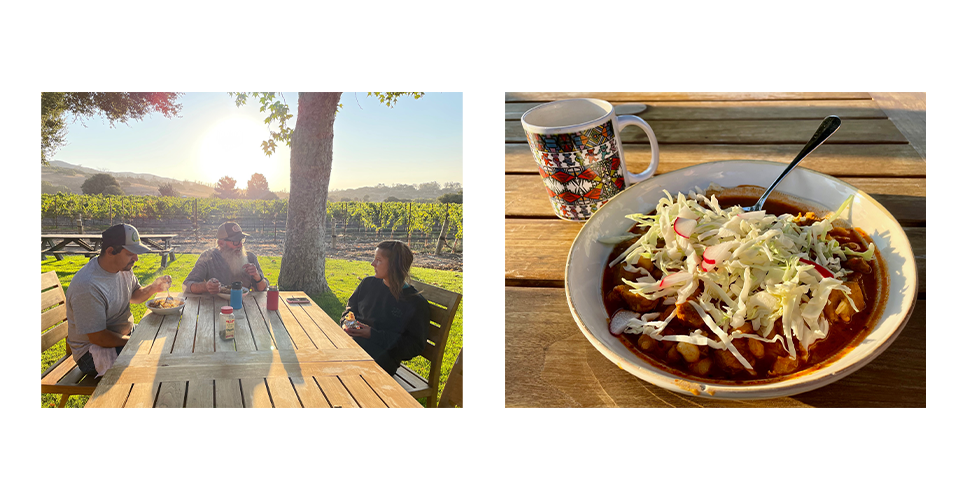

Sometime around now stomachs start to growl and we can actually hear the rumble over Bob Marley’s wailing. Time for lunch! Typically the crew breaks for lunch around 10 am and eats together somewhere on the property, usually, they bring their own, or Chad sports it. Sometimes they open a bottle to discuss and enjoy… harvest is a special time, and they like to create memorable moments together… otherwise known as #MelvilleMoments (yeah, yeah, a gratuitous marketing plug.)

After bellies are full, there’s more work to do in the cellar… analyzing the numbers (ie: sugar percentage), pressing Chardonnay, or checking on it fermenting in barrel. “We take some out and measure the temperature, swirl it around in a glass, looks good… put our nose in it… smells good… give it a taste,” says Chad, “The nose is one of the most important tools in winemaking.” More Chad talking Melville. We get it—a nose knows.

When labs and cellar duties have been checked off for the afternoon, the second round of punch-downs goes from 2-4 pm, then the cellar crew workday is finally done, a 12–hour day! From 4-10 pm things are pretty quiet… until the vineyard crew begins their round of picking overnight again… and the cycle continues tonight, tomorrow, and the next day, and the next. There’s more coffee, more cleaning… picking, processing, and punch-downs, and a long end in sight.

In mid to late November, when the last block has been picked… although there’s ALWAYS still more work to be done in the cellar… the full activities of harvest will come to an end… the crew will have a moment to rest their weary eyes and feet (and admire their built-up strength from the punch-downs.)

The entire staff will get together for an end-of-harvest celebration and look back on this magical time with joy and gratitude… Chad will pick a few bottles to open and we’ll all toast to another harvest year well-done.

Okay, so that’s it… the real dirt on the cellar crew… nothin’ too saucy, nothin’ too gritty… except for Lee’s boots after a long day. Thank you for coming along on this journey with us! We look forward to tasting the fruits of this harvest in the future and hope you will join us with a glass sometime as well.